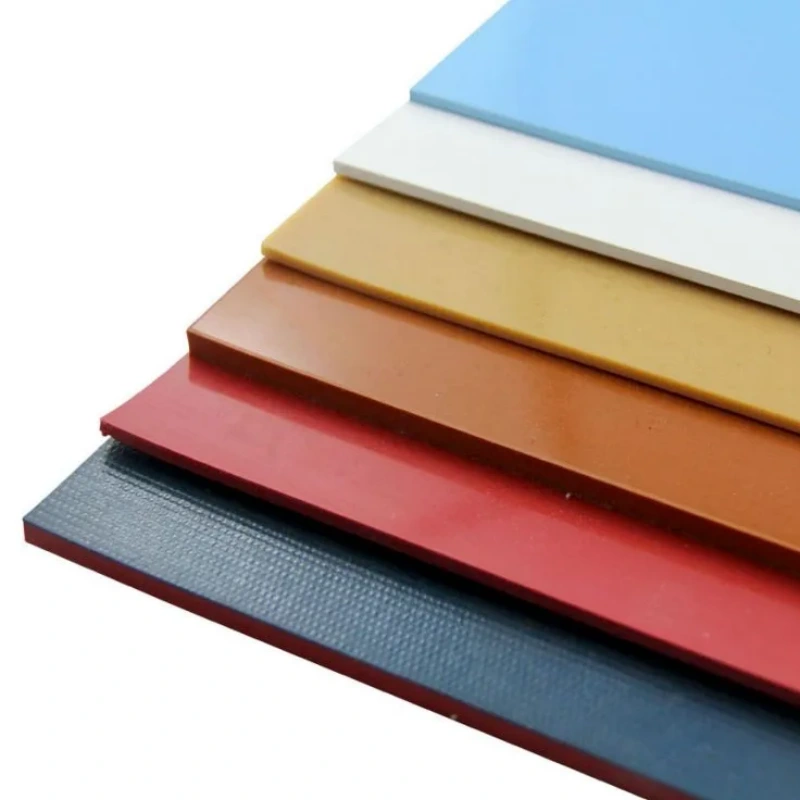

EP Conveyor Belt (Polyester/Polyamide conveyor belt)

EP conveyor belt adopts high-strength polyester and nylon as the skeleton material, combined with multi-layer fabric structure design to ensure excellent tensile strength, abrasion resistance and impact resistance. Its structure includes wear-resistant upper surface rubber and strong layers, which can withstand high loads and impacts.

EP conveyor belts are widely used in steel, coal mining, building materials, cement, chemical and other industries for material handling. Designed for long time and high intensity use, they are especially suitable for handling rough materials and can maintain stable operation in harsh environments.

EP conveyor belt is composed of high strength polyester and nylon woven composite material with multi-layer fabric design, which has the following features:

- High strength and tensile resistance

The combined polyester and nylon construction provides superior tensile strength to cope with heavy-duty transportation needs, avoiding frequent belt replacement and maintenance. - High abrasion resistance

The combination of upper surface rubber and strong layer material makes the conveyor belt perform well when transporting rough materials (e.g. coal, ore, etc.), which can prolong the service life and reduce the frequency of replacement. - Impact resistance

Designed with enhanced impact resistance, it is particularly suitable for applications in mining, steel and other industries where there are large shock loads, reducing the risk of equipment downtime and belt damage. - Strong corrosion resistance

The surface and core layer of EP conveyor belts are resistant to oil and chemical corrosion, suitable for chemical and oil polluted environments, guaranteeing continuous and stable operation under harsh conditions. - Low elongation for reduced maintenance costs

The low elongation design ensures that the belt body maintains its transmission efficiency after a long period of operation, which reduces the need for frequent adjustments and maintenance and effectively lowers the overall operation and maintenance costs. - Wide adaptability to meet diversified needs

EP conveyor belts are suitable for a wide range of high-strength applications, especially suitable for mining, steel, coal and other industries, and can also be customized in different widths and thicknesses to meet the special needs of different industries and working conditions.

The high performance and strong adaptability of EP conveyor belts make them ideal for many high-load applications. Whether transporting rough materials for long periods of time or meeting the challenges of harsh environments, EP conveyor belts provide efficient and reliable solutions that help companies increase productivity and reduce operating costs.

Textile Carcass Conveyor Belt Data |

||||||||||||||

| Carcass | Carcass Structure | Carcass Type |

Carcass Thickness [mm/p] |

Strength[N/mm] | Cover Thickness [mm] |

Width mm |

||||||||

| Warp | Weft | 2ply | 3ply | 4ply | 5ply | 6ply | top Cover |

bottom cover |

||||||

| Polyester [EP] |

Polyester | Nylon | EP100 | 1.00 | 200 | 300 | 400 | 500 | 600 | 1.5-30 | 0-20 | 300-5600 | ||

| EP125 | 1.00 | 250 | 375 | 500 | 625 | 750 | ||||||||

| EP150 | 1.00 | 300 | 450 | 600 | 750 | 900 | ||||||||

| EP200 | 1.20 | 400 | 600 | 800 | 1000 | 1200 | ||||||||

| EP250 | 1.40 | 500 | 750 | 1000 | 1250 | 1500 | ||||||||

| EP300 | 1.60 | 600 | 900 | 1200 | 1500 | 1800 | 2-30 | |||||||

| EP350 | 1.70 | 700 | 1050 | 1400 | 1750 | 2100 | ||||||||

| EP400 | 1.90 | 800 | 1200 | 1600 | 2000 | 2400 | ||||||||

| EP500 | 2.10 | 1000 | 1500 | 2000 | 2500 | 3000 | ||||||||

| EP630 | 2.60 | 1260 | 1890 | 2520 | 3150 | 3780 | ||||||||

Adhesion Strength and Elongation |

|||||

| Carcass Type [EP/NN] |

Adhesion | Elongation | |||

| Between Plies N/MM |

Between Rubber and and Carcass N/MM | Longitudinal Elongation At Break At All Thckness of Belt %≥ |

Longitudinal Reference Tensile Rate at All Thickness of Belt %≤ |

||

| Cover Thickness [0.8-1.5mm] |

Cover Thickness >1.5mm |

||||

| Mean Value | ≥4.5 | ≥3.2 | ≥3.5 | 10 | 2 |

| Lowest Data | ≥3.9 | ≥2.4 | ≥2.9 | 10 | 2 |