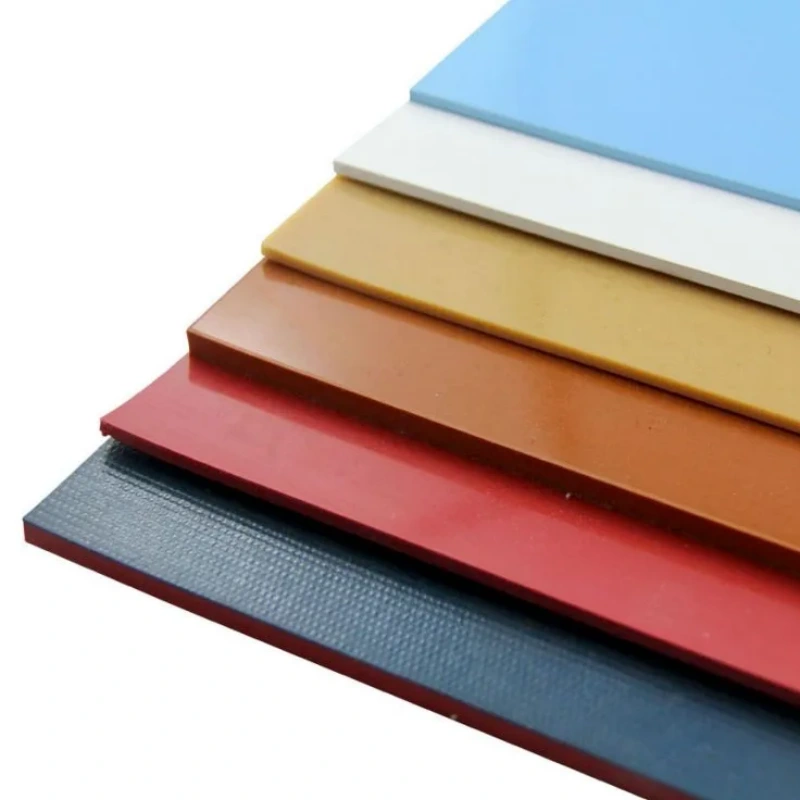

PVC Cleats

PVC Cleats are specialized accessories used with PVC conveyor belts to assist in material handling, particularly for inclined and vertical systems. Available in various heights, sizes, and configurations, these cleats help guide and elevate materials, ensuring safe and efficient transportation in different applications.

Features

- Versatile design: PVC cleats are designed to work seamlessly with PVC conveyor belts, improving material handling in various settings.

- Customization options: Available in a variety of sizes, heights, and shapes to meet specific operational requirements.

- Durable material: Made from high-quality PVC, providing long-lasting performance and resistance to wear and tear.

- Enhanced material flow: Cleats help direct materials, preventing them from slipping or falling off during transportation, especially in inclined conveyors.

- Improved performance: Allows for the efficient transport of materials at steeper angles without the risk of material spillage.

Properties and Advantages

- Improved transport stability: Cleats prevent materials from falling off, ensuring that goods stay in place during transit, even on inclined or vertical conveyor systems.

- Customizable design: Choose from various cleat shapes, sizes, and spacing configurations to fit your specific material and system requirements.

- Durability: Made from high-quality PVC, ensuring resistance to wear and long service life, even in challenging environments.

- Corrosion resistance: PVC material is resistant to moisture, oils, and chemicals, providing reliable performance in a range of industries.

- Increased operational efficiency: Cleats help organize materials, enabling smoother and more efficient conveyor operations.

Applications

- Inclined and vertical conveyors: Ideal for systems that move materials at an angle, preventing materials from falling or slipping during transport.

- Material handling: Commonly used in food processing, packaging, mining, and construction industries for bulk material transportation.

- Industrial environments: Suitable for environments where materials need to be lifted, sorted, or moved on conveyors with varying angles.

- Chemical and mining industries: Effectively transports abrasive or reactive materials without spillage, even in high-temperature or high-moisture environments.

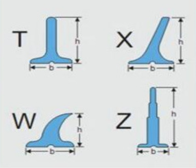

| Type | Cross-section schematic | Material | Model No. | Sizebxh [mm] | Color | Operating temperature [°C] | Minimum turning diameter (surface) [mm] | Minimum turning diameter (bottom) [mm] |

| Cleat |  |

PVC | T10 | 10×10 | White/Green/Lime | -10/+70 | 40 | |

| PVC | T20 | 20×20 | White/Green | -10/+70 | 90 | |||

| PVC | T30 | 25×30 | White/Green | -10/+70 | 120 | |||

| PVC | T40 | 25×40 | White/Green | -10/+70 | 120 | |||

| PVC | T50 | 25×50 | White/Green | -10/+70 | 120 | |||

| PVC | T60 | 38×60 | White/Green | -10/+70 | 150 | |||

| PVC | W35 | 28×35 | White/Green | -10/+70 | 130 | |||

| PVC | X50 | 30×50 | White/Green | -10/+70 | 80 | |||

| PVC | X60 | 30×60 | White/Green | -10/+70 | 80 | |||

| PVC | X80 | 43×80 | White/Green | -10/+70 | 100 | |||

| PU | T20 | 12×20 | Green | -20/+80 | 40 | |||

| PU | T30 | 12×30 | White/Green | -20/+80 | 45 | |||

| PU | Z120 | 40×120 | White | -20/+80 | 300 | |||