Top Industrial Conveyor Belt Manufacturers In World

1.Shouhuo Rubber&Plastic

2.Tiantie Industrial

3.Continental AG

4.Bridgestone

5.Fenner Dunlop

6.Sempertrans

7.Habasit

8.Goodyear

9.Mitsuboshi

10.Bando

1.Industrial Conveyor Belt Manufacturers Market Trends and Applications

Global Rubber Conveyor Belt Market and its Growth Trends

Rubber conveyor belts have been widely used in several industries as one of the crucial equipment in industrial automation. According to the latest market research data, the global rubber conveyor belts market is approaching USD 5.5 billion by 2024 and is expected to reach USD 6.7 billion by 2027, growing at a CAGR of 6.5%. This growth trend is mainly driven by factors such as accelerated industrial automation, promotion of eco-friendly materials, and growing demand for e-commerce.

As the global manufacturing and logistics industries continue to grow, rubber conveyor belts are expanding their applications and becoming a key component of modern production and transportation processes. Many rubber conveyor belts are not only capable of basic material conveying, but also have special features such as high temperature resistance, anti-abrasion and anti-static properties, which enable them to adapt to more complex working environments and ensure an efficient and safe transportation process.

Key drivers

- Industrial automation:As more and more industries are developing in the direction of automation, rubber conveyor belts play an increasingly important role as an important part of automated production lines. For example, in automobile manufacturing and electronic assembly lines, rubber conveyor belts transport parts efficiently, greatly reducing manual intervention and improving production efficiency.

- Use of environmentally friendly materials:With the rise of environmental awareness, rubber conveyor belt manufacturers are also gradually applying environmentally friendly materials to their production processes, using green materials such as recyclable rubber, thus improving the sustainability and environmental performance of their products.

- Growing demand for e-commerce:The rapid development of the e-commerce industry has driven changes in the logistics industry. Rubber conveyor belts are widely used in warehousing, sorting and distribution systems, helping companies to improve processing speed and sorting accuracy, and meeting the needs of the rapid development of e-commerce business.

- Mining and energy demand:The growth in the mining of resources such as coal and iron ore directly drives the demand for heavy conveyor belts.

Main application industries of conveyor belts

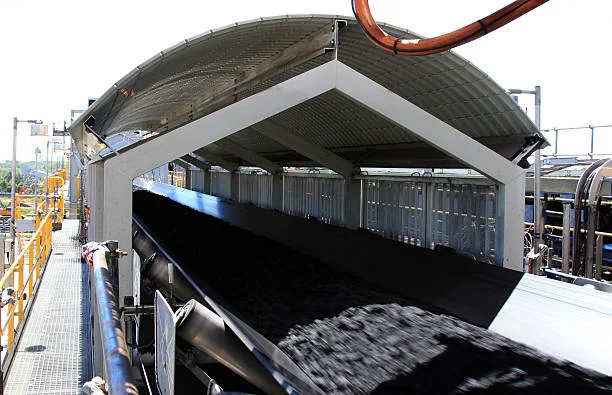

- Mining:Rubber conveyor belts are widely used in the mining industry, especially in the transportation of heavy materials such as coal and ore, where high temperature and abrasion resistant rubber conveyor belts play a vital role. Steel cord rubber conveyor belts and high temperature rubber conveyor belts perform particularly well in such high load and high temperature environments, ensuring efficient and safe transportation of materials.

- Manufacturing industry:The application of rubber conveyor belts in the manufacturing industry mainly focuses on the assembly, packaging and transportation of products. For example, in the production lines of automobiles, electronic equipment and other products, rubber conveyor belts can efficiently transfer parts and semi-finished products to various work stations, greatly improving production efficiency and product consistency.

- Food Processing:The food industry has extremely high requirements for hygiene standards. Food-grade conveyor belts must have corrosion resistance and easy cleaning characteristics. They are widely used in meat, dairy and baked product processing lines.

- Logistics and Distribution:In logistics and distribution centers, rubber conveyor belts are used for parcel sorting and goods transportation, which can improve the speed and accuracy of logistics processing, especially in intelligent warehouses and automated sorting systems, where the role of rubber conveyor belts is crucial.

- Agriculture and Pharmaceuticals: In agriculture, rubber conveyor belts are widely used in the sorting and handling of agricultural products, reducing the cost and labor intensity of manual handling. In the pharmaceutical industry, rubber conveyor belts are used in the transportation and packaging of pharmaceuticals, ensuring safety and compliance throughout the production process.

2. Ranking of Top 10 Industrial Conveyor Belt Manufacturers

Selection Criteria

For the ranking of the Top 10 Industrial Conveyor Belt manufacturers, we evaluate based on the following five criteria to ensure that the comprehensive performance of each company can fully demonstrate its leading position in the rubber conveyor belt industry.

1.Technological Innovation

- Reason for sorting:Technological innovation is the core factor in measuring the competitiveness of a conveyor belt manufacturer. As industrial production increasingly relies on automation and intelligent technology, manufacturers must continue to invest in research and development to improve product performance and efficiency. For example, the rise of smart conveyor belts in recent years has integrated Internet of Things technology to monitor conveyor belt tension, wear, temperature and other indicators in real time, which can greatly reduce downtime and improve production efficiency. Therefore, in the selection process, whether breakthroughs can be made in technological innovation has become an important basis for sorting.

- Specific performance:Leading Industrial Conveyor Belt manufacturers continue to optimize the material science and production process of conveyor belts, promote the use of green and environmentally friendly materials, develop high-performance conveyor belts that are resistant to extreme environments, and improve product durability and safety.

2.Product quality

- Reason for sorting:Product quality directly affects the manufacturer’s market reputation and customer satisfaction, especially rubber conveyor belts must withstand huge loads and wear in extreme environments. High-quality conveyor belts can maintain efficient and stable operation in harsh environments, reduce maintenance and replacement frequency, and bring higher long-term value to customers. Therefore, product quality is a very critical criterion in the ranking.

- Specific performance:The rubber conveyor belts provided by the top Industrial Conveyor Belt manufacturers have excellent properties such as super wear resistance, high temperature resistance, and corrosion resistance, and can maintain stable transportation effects in multiple high-load and extreme environments, thereby reducing failure rates and maintenance costs during long-term use.

3.Industry influence and reputation

- Reason for sorting:Industry influence and reputation represent the company’s position in the global market and customer recognition of its products. Especially in the international market, long-term accumulated brand influence and customer loyalty will directly affect the company’s competitiveness in the industry. Companies with good reputations are usually able to attract more partners and long-term customers and maintain a stable market share.

- Specific performance:Industrial Conveyor Belt manufacturers that can establish a strong brand influence worldwide, such as through high-quality after-sales service, stable supply chain management and high customer satisfaction, are usually able to stand out in the fierce market competition. The company’s performance in international industry exhibitions, conferences, etc., customer feedback and word of mouth are also important factors affecting the company’s ranking.

4.R&D investment and technological leadership

- Ranking reason:Continuous R&D investment is the key to maintaining technological leadership. The industry is advancing rapidly, and manufacturers must optimize the functions and performance of products through continuous innovation and research to maintain the industry’s competitive advantage. Companies that can significantly improve the technical performance of their products and meet the changing needs of customers usually occupy a higher position in the market.

- Specific performance:For example, some Industrial Conveyor Belt manufacturers continue to invest heavily in the research and development of high-temperature resistant, corrosion-resistant, and high-strength rubber conveyor belts, and launch new conveyor belt products that meet environmental standards. R&D is not only reflected in the improvement of the product itself, but also includes innovation in production processes and improvement of production efficiency.

5.Production efficiency and delivery capability

- Ranking reason:In a global supply chain, production efficiency and delivery capability are crucial to meeting customer needs. Customers require not only high-quality products, but also timely delivery and quick response capabilities. Companies that can quickly produce and deliver according to market demand can maintain their advantages in the fierce competition.

- Specific performance:Whether Industrial Conveyor Belt manufacturers can operate efficiently during the production process and ensure timely delivery of each order while ensuring large-scale production will directly affect customer satisfaction and market share. Manufacturers with global supply chains are usually able to provide flexible delivery times and fast supply responses, thereby ensuring their reputation and competitiveness among customers.

Top 10 Industrial Conveyor Belt Manufacturers

| Company Name | Website |

| Shouhuo Rubber&Plastic | https://shouhuochn.com |

| Tiantie Industrial | https://conveyorbeltchn.com |

| Continental | https://www.continental.com/en/ |

| Bridgestone | https://www.bridgestone.com/ |

| Fenner Dunlop | https://fennerdunlopamericas.com/ |

| Sempertrans | https://conveyor-belts.semperitgroup.com/ |

| Habasit | https://www.habasit.com/ |

| GoodYear | https://goodyearrubberproducts.us/ |

| Mitsuboshi | https://www.mitsuboshi.com/english/ |

| Bando | https://www.bandogrp.com/eng/ |

1.Shouhuo Rubber & Plastic

- Technology Innovation:Shanghai Shouhuo has developed a flame retardant and antistatic integrated rubber formula and passed the coal mine MT914 safety certification to ensure the safety of conveyor belts in mining and port environments.

- Product Quality:Using refining equipment imported from Germany, the precise control of the vulcanization process has reached the advanced level of the industry, ensuring stable and reliable product quality.

- Industry Influence and Reputation: As a major supplier in China’s coal and port industries, Shanghai Shouhuo has participated in the formulation of multiple national standards and has a high reputation in the industry.

- R&D Investment and Technology Leadership:Cooperating with universities to study bio-based rubber alternative technologies to reduce carbon emissions and promote the development of environmentally friendly conveyor belts.

- Production Efficiency and Delivery Capability: The AGV logistics system was introduced in the Jiangsu production base to improve the raw material turnover efficiency and accelerate the production and delivery speed.

2.Tiantie Industrial

- Technology Innovation:Tiantie has developed ultra-long-distance steel cord conveyor belt technology, which supports the transportation of more than 30 kilometers of a single conveyor belt, providing efficient material transportation solutions for mining and heavy industry.

- Product quality:It complies with DIN 22131 standard, and the tensile strength reaches 6000N/mm², ensuring the stability of the product under high-load environment.

- Industry influence and reputation: Tiantie is a major supplier in the mining market in the Asia-Pacific region, serving regional projects of many international mining groups, and has a strong industry influence.

- R&D investment and technological leadership:The company has built an intelligent testing center to simulate extreme mining environments to optimize product design and improve the performance of conveyor belts under harsh conditions.

- Production efficiency and delivery capabilities:Bonded warehouses have been set up in Southeast Asia, shortening the delivery cycle of cross-border projects and improving the ability to respond to market demand.

3.Continental AG

- Technological innovation: Continental AG has developed air-supported conveyor belts, using air suspension technology to reduce friction resistance and energy consumption, and has launched self-healing rubber coating technology to automatically fill small surface cracks.

- Product quality:It adopts a multi-layer composite rubber structure, obtains ISO 340 fire protection certification and FDA food grade certification, and is suitable for multiple industrial and food processing fields.

- Industry influence and reputation: It is a leader in the standardization of conveyor systems in the European automotive manufacturing industry and is trusted by customers around the world.

- R&D investment and technological leadership:A materials research center has been established in Berlin, focusing on the research and development of recyclable rubber and bio-based materials to promote the application of environmentally friendly technologies.

- Production efficiency and delivery capabilities:Standardized and modular production processes are implemented in 12 production bases around the world to ensure efficient production and timely delivery of products.

4.Bridgestone Corporation

- Technological innovation:Bridgestone has developed Kevlar® reinforcement technology to effectively prevent longitudinal tearing and improve the durability of rubber conveyor belts.

- Product quality: In compliance with JIS K6322 standards, the wear layer thickness tolerance is controlled within ±1mm to ensure consistent high-quality performance of the product.

- Industry influence and reputation:Bridgestone is a core supplier in the Southeast Asian mining market and has participated in the revision of ISO international standards for conveyor belts.

- R&D investment and technological leadership:A global R&D center has been established in Kyushu, Japan, with an annual investment of more than US$100 million in the development of high-performance conveyor belt technology.

- Production efficiency and delivery capabilities:Adopting the JIT (Just in Time) model, with industry-leading inventory turnover, ensuring efficient production and fast delivery.

5.Fenner Dunlop

- Technological innovation:The multi-layer fabric core design (DynaTech®) significantly improves the wear resistance of rubber conveyor belts, especially for heavy-duty environments such as mining.

- Product quality:Complies with the Australian mining standard AS 4606, suitable for extreme temperature environments (-40°C to 120°C), ensuring that the conveyor belt can still work stably at high or low temperatures.

- Industry influence and reputation:As a core partner of global mining giants Rio Tinto and BHP Billiton, Fenner Dunlop has an important position in the global mining industry.

- R&D investment and technological leadership: Developed integrated non-lubricated bearing technology, reducing maintenance requirements and improving the reliability and durability of conveyor belts.

- Production efficiency and delivery capabilities:Set up regional service centers in South Africa and Brazil to provide fast maintenance support to ensure seamless operation of customers’ production lines.

6.Sempertrans

- Technological innovation:Sempertrans has developed a zero-halogen flame retardant formula that complies with EU REACH regulations and is suitable for high-temperature working environments such as steel and coal mines.

- Product quality:Ceramic coating technology is used to improve the high temperature resistance of rubber conveyor belts (up to 800°C) and ensure their service life in extreme temperatures.

- Industry influence and reputation:It has a market share of more than 60% in the European steel industry and is widely used in steel, coal mining and other fields.

- R&D investment and technological leadership:Cooperate with Fraunhofer Institute to develop high-temperature materials and promote the continuous upgrading of rubber conveyor belt technology.

- Production efficiency and delivery capacity:Fully digital production management has been achieved in the Polish factory, which has improved production efficiency and consistency of product quality.

7.Habasit AG

- Technological innovation: Habasit has developed a modular plastic conveyor belt design (MPB) that supports quick disassembly for cleaning and improves the hygiene standards of the production line.

- Product quality:Obtained FDA and EU 10/2011 food grade certification, with a surface roughness controlled at ≤2μm, ensuring high standards in the food processing industry.

- Industry influence and reputation:The global food processing industry has the largest market share of light conveyor belts and has become one of the industry standard setters.

- R&D investment and technological leadership:Develop low-friction materials to reduce energy consumption in equipment operation, and further improve the efficiency and energy-saving effect of conveyor belts.

- Production efficiency and delivery capabilities:The Swiss headquarters factory achieves 48-hour delivery of small-volume customized orders to ensure rapid response to customer needs.

8.Goodyear

- Technological innovation:Developed Flexsteel® steel wire rope core technology, which enhances impact tolerance through multi-layer steel wire braiding and improves the damage resistance of conveyor belts.

- Product quality: Certified by MSHA (Mine Safety and Health Administration), oiliness and aging resistance are industry-leading, suitable for mining and agriculture and other fields.

- Industry influence and reputation:A core supplier in the North American agricultural and logistics industries, serving major grain traders and airport logistics systems, with extensive industry influence.

- R&D investment and technological leadership:Invest in automated production lines to improve the large-scale production efficiency of high-load conveyor belts.

- Production efficiency and delivery capabilities: Localized production is achieved in the Ohio factory to cover the needs of customers in the Midwest of the United States and shorten delivery cycles.

9.Mitsuboshi

- Technological innovation:Mitsuboshi has developed Silent Conveyor Belt technology, which reduces operating noise to below 65dB through an internal damping layer, suitable for industries that require a low-noise environment.

- Product quality:Oil-resistant synthetic rubber has passed the JIS K6258 standard, suitable for oil-contaminated environments in automobile manufacturing, ensuring long-term stable operation.

- Industry influence and reputation:It provides conveyor belts to Japanese automakers (such as Toyota and Honda) and is their preferred supplier. Mitsuboshi has an important market share in the Japanese and global automotive industries.

- R&D investment and technological leadership:Develop carbon fiber reinforced materials to expand the application of conveyor belts in high-demand fields such as aerospace, and improve product durability and performance.

- Production efficiency and delivery capabilities:Adopt a lean production model to support flexible small-batch and multi-batch order delivery to meet global customer needs.

10.Bando Chemical Industries

- Technological innovation:Bando has developed anti-static coating technology with a surface resistance controlled between 10^6-10^9Ω, which meets the requirements of semiconductor clean rooms and is suitable for high-precision industrial applications.

- Product quality:Salt spray corrosion resistance has passed the JIS Z2371 standard, which is particularly suitable for environments such as ports and ship transportation, and has excellent corrosion resistance and reliability.

- Industry influence and reputation:Bando is a core supplier of special conveyor belts for Japan’s high-end manufacturing industry (such as Sony and Toshiba), and is widely used in multiple high-tech industries.

- R&D investment and technological leadership:Cooperate with the Japan Aerospace Exploration Agency (JAXA) to verify the stability of materials in space environments and promote technological progress in ultra-high-performance conveyor belts.

Production efficiency and delivery capabilities: The full process automation is achieved in the Osaka factory, shortening the delivery cycle of orders in the Asia-Pacific region to 10 days, significantly improving production efficiency and response speed.

3. Mining Conveyor Belt Manufacturers

The Importance of Mining Conveyor Belts

The conveyor belts in the mining industry play a vital role in the transportation of heavy materials such as coal and ore. Mining conveyor belts can not only improve transportation efficiency, but also significantly reduce labor costs. Due to the particularity of the mining operating environment, conveyor belts must have strong load-bearing capacity, wear resistance and corrosion resistance, and be able to adapt to extreme working conditions.

With the expansion and modernization of the global mining industry, more and more mining companies are turning to high-performance conveyor belts to improve overall production efficiency, ensure safety and reduce long-term operating costs.

Technological Innovation

1.Smart Conveyor Belt System

- Technical Implementation:The smart conveyor belt system embeds fiber optic sensors and vibration monitoring modules inside the belt to collect tension, temperature and wear data in real time, and generates predictive maintenance reports through edge computing and cloud platform analysis. These intelligent systems can identify potential equipment failures in advance, thereby reducing downtime and optimizing maintenance processes.

- Practical Application:The SIMARIS system developed by Siemens in Germany and Continental has been applied to multiple mining projects, which can warn of potential failures 48 hours in advance, reduce unplanned downtime by 35%, and reduce maintenance costs by 28%. The widespread application of this technology has significantly improved the production efficiency and equipment utilization of mining companies.

2.Extreme environment resistant conveyor belts

- Material breakthrough:Extreme environment resistant conveyor belts use ceramic-aramid composite coatings (such as Sempertrans) or silicon-based high temperature resistant rubber (such as Bridgestone), which enables the conveyor belts to withstand the challenges of extreme temperature ranges. The temperature range is extended to -60°C to 800°C, and the service life is 2 times longer than that of traditional products.

- Scenario adaptation:In the Escondida copper mine in Chile, low temperature resistant conveyor belts are used in an extremely cold environment at an altitude of 3,000 meters. These conveyor belts have not experienced brittle fractures in five years, greatly improving the stability and safety of mining transportation.

3.Energy saving and sustainable design

- Structural innovation:In the design of the conveyor belt, the use of lightweight carbon fiber cores (such as Habasit AG) reduces the belt’s own weight by 30%, and is matched with permanent magnet synchronous motors to reduce energy consumption by 25%. In addition, Fenner Dunlop’s “lubricant-free bearing” design also effectively reduces energy consumption during maintenance and reduces total operating costs.

- Circular economy: Continental’s “EcoCycle” recycling program has achieved a remanufacturing rate of over 60% for old belts, helping customers reduce procurement costs by 30% and playing a positive role in reducing environmental impact. This program has promoted the development of the conveyor belt industry in a more sustainable direction.

4.Enhanced safety functions

- Fire retardant: Sempertrans’ halogen-free flame-retardant conveyor belts are certified by EN 45545-2, and their combustion smoke toxicity is less than 0.1%. These conveyor belts are widely used in underground platinum mining in South Africa. Due to their excellent fire resistance, the fire accident rate has been reduced to zero, ensuring the safety of miners.

- Automatic deviation correction:Fenner Dunlop’s DynaTrac laser alignment system monitors the position of the belt in real time. When the belt deflects more than 5 mm, the system automatically adjusts, reducing the occurrence of deviation accidents and avoiding material loss and equipment damage caused by the conveyor belt deviating from the track. The application of this system has reduced deviation accidents by 95%, greatly improving the stability and safety of the conveyor belt.

Global Market and Major Import Markets

The demand for mining conveyor belts in the global market is growing, mainly driven by industrialization and mining resource development. The following are the major import markets analyzed in detail:

North America

- Market Analysis:The North American market is an important region for global mining conveyor belt demand, especially the United States and Canada. The United States is the world’s second largest coal producer and one of the world’s leading metal ore producers. The demand for shale oil mining in the United States and the transportation of Canadian oil sands drives the demand for low-temperature resistant (-50°C) and anti-static conveyor belts. For example, the Canadian Suncor oil sands project purchased Bridgestone anti-static belts, with a single order of more than US$80 million.

- Data:The mining equipment and conveyor belt market in the United States and Canada is expected to reach a market size of US$3.2 billion in 2025, with an average annual growth rate of about 5%. Especially in the metal mine and coal mining industries, the demand for efficient conveyor belt systems continues to rise.

- Demand drivers:With the improvement of mining automation and the increase in demand for energy efficiency, the demand for high-performance, energy-saving and intelligent conveyor belts in the North American market continues to rise, driving the growth of demand for advanced conveyor belt products. In particular, the penetration rate of intelligent monitoring systems (such as Siemens SIMARIS) and recyclable materials (such as Continental’s EcoPlus series) has increased year by year, and the purchase volume of intelligent conveyor belts in North America increased by 22% in 2023.

Europe

- Market analysis:Europe is an important market for global mining and manufacturing, especially in countries such as Germany, France and the United Kingdom, where the industrialization process is relatively mature, and the demand for conveyor belts in mining and heavy industry has grown steadily. Europe not only has large mines, but also has a strong automotive and logistics industry, and conveyor belt technology is widely used. The EU’s “Green Mine” plan has promoted the use of environmentally friendly conveyor belts and forced mining companies to use recyclable materials.

- Data: According to data from the European Statistical Office (Eurostat), the market size of related equipment for mining activities in Europe exceeds US$3 billion each year, among which conveyor belts occupy an important position. In 2019, the market size of industrial conveyor belts in Europe has reached approximately US$1.4 billion, with an average annual growth rate of 6%.

- Demand drivers: With the strict implementation of environmental regulations, especially the purchase of Sempertrans halogen-free conveyor belts by ThyssenKrupp Steel in Germany, the unit price is 15% higher than traditional products, but it reduces carbon emissions by 40%. The European market has a strong demand for high-performance, environmentally friendly conveyor belts, which has promoted the development of green mine plans and high-end applications (such as the purchase of Tiantie Industrial ultra-long distance conveyor belts by LKAB Iron Mine in Sweden).

Asia Pacific

- Market analysis:The Asia Pacific region is the fastest growing market in the world, especially in countries such as China, India and Japan. In China, the rapid development of mining and infrastructure construction has greatly promoted the demand for efficient conveyor belt systems. As an emerging mining power, India has also become a major market for conveyor belt products with the development of its mineral resources.

- Data:According to a report by the China Mining Association, China is the world’s largest coal producer and consumer, with an annual coal output of more than 3.8 billion tons. The demand for mining conveyor belts continues to grow with the expansion of mines and the construction of automated mining facilities. It is expected that by 2026, the compound annual growth rate (CAGR) of China’s mining conveyor belt market will reach 7.5%.

- Demand drivers:Demand in the Asia-Pacific region mainly comes from coal, metal mines and infrastructure construction. BHP Billiton and Rio Tinto in Australia purchase more than 150,000 meters of conveyor belts each year, preferring Fenner Dunlop’s multi-layer composite fabric structure products with a wear life of 10 years. With industrial upgrading, Southeast Asia, such as the Freeport copper mine in Indonesia, has deployed the Tiantie Industrial AI monitoring system, reducing maintenance costs by 25%.

Middle East and Africa

- Market analysis:With the rapid development of the mining, construction and oil and gas industries in the Middle East and Africa, the demand for efficient conveyor belt systems is also gradually increasing. Especially in South Africa, the United Arab Emirates and Saudi Arabia, the rapid development of the mining industry has driven the demand for mining conveyor belts. Africa is a region rich in mineral resources in the world, and with the advancement of mining and infrastructure construction, the demand for conveyor belts continues to grow.

- Data:According to statistics from the African Mining Association, the mining conveyor belt market in Africa reached US$580 million in 2021, and the market size is expected to grow to US$900 million by 2026, with an average annual growth rate of 10%.

- Demand drivers:Increased investment in mining and infrastructure construction in the Middle East and Africa, especially in Saudi Aramco’s purchase of fire-resistant and corrosion-resistant conveyor belts for oil and gas pipeline construction, and the growing demand for ceramic-coated conveyor belts at the Sibanye-Stillwater gold mine in South Africa. The African market is more sensitive to cost-effective lightweight conveyor belts, and Indian manufacturers (such as Tega Industries) have occupied 45% of the market share through low-price strategies.

South America

- Market analysis:South America, especially Brazil and Argentina, is an important producer of global mineral resources, and the demand for mining and agriculture has driven the growth of the conveyor belt market. Brazil is one of the world’s largest iron ore producers, while Argentina and Chile also play an important role in the mining of copper and lithium mines, all of which have brought a lot of demand to the conveyor belt market.

- Data:According to a report from the Latin American Mining Association, the market size of mining equipment in South America reached US$860 million in 2020, of which mining conveyor belts accounted for 13%, and is expected to grow to US$1.4 billion by 2025, with a compound annual growth rate of 7%.

- Demand drivers:Chile’s Codelco is the world’s largest copper miner, replacing more than 80,000 meters of conveyor belts each year and purchasing Bridgestone’s tear-resistant conveyor belts. Agricultural demand in the South American market, especially soybean exports from Brazil, has also driven an increase in demand for port conveyor systems, and demand for modular maintenance design has grown significantly.

4.Challenges and Opportunities

Challenges

1.Trade Barriers and Policy Restrictions

- Carbon Tariff Pressure:The EU’s Carbon Border Adjustment Mechanism (CBAM) imposes a carbon tax on imported conveyor belts. After full implementation in 2026, Asian manufacturers’ export costs may increase by 15%-20%. For example, Indian manufacturers need to pay an additional 30 euros in carbon tax per ton of rubber. This policy will affect production costs and pricing strategies, especially in the European market.

- Differences in technical standards: Technical certification requirements vary from market to market. North America’s MSHA certification, Europe’s CE certification, and Japan’s JIS standards are incompatible with each other. Companies need to invest millions of dollars in multi-regional certification. This makes market expansion more difficult for small and medium-sized conveyor belt manufacturers, increasing the complexity and cost of international business.

- Geopolitical risks: The conflict between Russia and Ukraine has led to supply chain disruptions in Eastern Europe, and Finnish manufacturers’ orders for conveyor belts exported to Russia have fallen by 70%. Geopolitical instability may affect raw material supply and delivery capabilities, increasing the risks faced by companies.

2.Fluctuation of raw material costs

- Rubber price fluctuations:In 2022, the price of natural rubber soared from US$1,500/ton to US$2,300/ton, resulting in a 5%-8% compression in the company’s gross profit margin. Some manufacturers were forced to increase product prices by 10%-15% to compensate for the cost increase.

- Steel import dependence: As European steel mills cut production due to the energy crisis, the price of special steels (such as SSAB Hardox) rose by 40%. This has had a significant impact on the production cost of steel cord conveyor belts, forcing companies to look for alternative raw materials or adjust pricing strategies.

- Insufficient supply chain resilience:After the COVID-19 pandemic, global ports were congested, resulting in a 30%-50% extension of delivery cycles. For example, the Chilean copper mine project lost more than US$100 million due to delayed delivery of conveyor belts. This issue reminds manufacturers that they need to improve resilience in global supply chain management to ensure timely delivery.

3.Pressure of technological substitution

- Automation competition:Unmanned trucks (such as Komatsu FrontRunner) have replaced traditional short-distance conveyor belts in some mines. In 2023, the size of the global unmanned truck market grew by 25%, posing a threat to the market share of conveyor belts within 200 kilometers. With the popularization of automated equipment, traditional conveyor belts are facing greater pressure to replace them.

- Impact of drone inspection:LiDAR drone technology is replacing manual inspections. The widespread application of this technology requires conveyor belt manufacturers to develop additional data interfaces to be compatible with third-party systems. This is expected to increase R&D costs by 20%, and also prompt manufacturers to pay more attention to intelligence and automation in product design.

- Risk of new material substitution:Carbon fiber reinforced plastic (CFRP) transmission modules challenge traditional rubber conveyor belts in the field of lightweighting, especially in the application of the automotive manufacturing industry. German manufacturers have begun to pilot the application of this new material in the automotive manufacturing field, which may affect the market share of conveyor belts in certain specific industries.

Opportunities

1.Growth potential in emerging markets

- Resource development in Africa:Guinea’s Simandou iron ore mine (the world’s largest undeveloped iron ore mine) is scheduled to be put into production in 2025, and it is expected that more than 50 kilometers of high-temperature resistant conveyor belts will be purchased, with a potential order amount of more than US$300 million. With the acceleration of mining development in the African market, the demand for conveyor belts will increase significantly.

- Mining upgrade in Central Asia: Uranium mines in Kazakhstan and copper mines in Mongolia are promoting automation transformation, and the demand for intelligent conveyor belts is expected to increase by 18% annually. For example, Bridgestone and Fenner Dunlop have established regional service centers in the region, further promoting the application of conveyor belts in this market.

- Latin American agricultural expansion:Brazil’s soybean exports are expected to reach 200 million tons in 2030, and the demand for upgrading port conveyor systems has increased significantly. The purchase volume of modular and corrosion-resistant conveyor belts is expected to increase by 12% annually. The expansion of this market will provide more opportunities for suppliers, especially in the fields of agriculture and logistics.

2.Post-war reconstruction demand release

- Ukrainian reconstruction plan:The EU has pledged to provide 50 billion euros in financial support for Ukraine’s infrastructure construction. The purchase demand for steel mills, cement plants and port conveyor belts is expected to reach 800 million euros, and European manufacturers (such as Sempertrans) will benefit from this market, especially for high-temperature resistant and heavy-load conveyor belts. The demand will increase significantly.

- Infrastructure upgrade in the Middle East:Saudi Arabia’s “Vision 2030” plans to invest $1.2 trillion to promote economic diversification, including the construction of smart logistics centers and mining new cities, which is expected to release tens of millions of meters of conveyor belt orders. The investment in this project not only promotes the development of the mining industry, but also drives the growth of demand for conveyor belts in the infrastructure and logistics industries.

3.Circular economy and sustainable development

- Old belt recycling and remanufacturing:Fenner Dunlop’s “old belt for new” service allows customers to return 1 km of old belts and get a 15% discount. This recycling plan helps customers save 30% of remanufacturing costs. In 2023, Fenner Dunlop’s recycling volume exceeded 20,000 kilometers, further promoting the green development of the conveyor belt industry.

- Application of bio-based materials:Habasit has developed a bio-based TPU (thermoplastic polyurethane) conveyor belt, 35% of which comes from renewable resources and reduces carbon emissions by 45%. The product has been purchased by companies such as Nestlé and Danone, further promoting the market application of environmentally friendly products.

- Green production process:Laser cutting technology is used instead of traditional stamping process to reduce rubber waste by 70%; in addition, water-based adhesives are used instead of solvent-based products, and VOC (volatile organic compound) emissions are reduced by 90%. This green production process helps reduce environmental pollution.

4.Automation and intelligent manufacturing needs

- AI-driven predictive maintenance:Siemens and Continental have jointly developed AI algorithms. By training models with historical data, the prediction accuracy of equipment failures has increased to 92%. This technology has reduced customers’ maintenance costs by 35% and effectively extended the service life of conveyor belts.

- Internet of Things integration:The application of 5G technology enables mine conveyor belts to achieve real-time return of full-link data. The 5G monitoring system deployed by Rio Tinto Group in Western Australia’s iron ore has successfully reduced downtime by 40%, further improving the efficiency of mining production and the reliability of equipment.

- Popularization of modular design:Bando Chemical’s “Plug & Play” joint system can reduce the maintenance time of conveyor belts from 8 hours to 1 hour, greatly improving customers’ production efficiency and helping companies reduce downtime.

5.Sustainability and future trends

1.Environmental protection practices

- Material substitution:The industry is accelerating the development of bio-based rubber and recycled materials, gradually replacing traditional petroleum-based raw materials and reducing dependence on non-renewable resources.

- Process upgrade: Promote low-carbon technologies such as laser cutting and low-temperature vulcanization to reduce production energy consumption and waste emissions.

- Recycling:The recycling and remanufacturing system of old belts is gradually improved to promote the improvement of resource utilization.

2.Future trends

- Intelligent penetration:The Internet of Things and AI technology are deeply integrated to achieve real-time monitoring and autonomous decision-making of the health status of conveyor belts.

- Lightweight design:The application of carbon fiber and nano-composite materials is expanded, taking into account both strength improvement and energy consumption reduction.

- Modular innovation:Modular components that can be quickly replaced have become mainstream, reducing maintenance downtime and material waste.

- Adaptation to extreme environments:Conveyor belt technology for special scenarios such as deep sea and space has entered the exploration stage.

3.Industry collaboration

- Standard unification:Promote global environmental protection and safety certification mutual recognition, and reduce corporate cross-border compliance costs.

- Cooperative innovation:Industry, academia and research jointly tackle core material and technology bottlenecks to accelerate green transformation.

6.Global Industrial Conveyor Belt Manufacturers Market Forecast (Next 5 Years)

The Industrial Conveyor Belt Manufacturers industry is in a critical period of technological iteration and policy transformation. The five-year cycle (2024-2028) can not only reflect the effectiveness of technology commercialization (such as intelligence, new material applications), but also avoid the uncertainty of long-term forecasts (such as geopolitics, raw material price fluctuations). At this stage, the strategic adjustments of leading companies, the implementation of regulations and changes in market demand will be intensively intertwined, forming an observable and actionable industry window period.

Core growth areas

1.Mining and energy fields

- From 2023 to 2028, the global mining conveyor belt market is expected to have an annual compound growth rate (CAGR) of 6.8%, and the demand for ultra-long distance (20 kilometers +) and high temperature resistant products will grow fastest (CAGR 9.2%).

- The mining of strategic resources such as lithium and rare earths has promoted the penetration rate of intelligent conveyor belts. By 2028, 50% of new mines will be equipped with sensor integration systems as standard.

2.Manufacturing and Logistics

- The demand for high-precision lightweight conveyor belts in the automotive and electronics industries will grow at an annual rate of **7.5%**, and the proportion of products with an error of ≤1 mm will increase from 15% to 30%.

- The expansion of e-commerce logistics centers will drive the modular plastic conveyor belt market, and the annual procurement volume in North America and Europe will increase by 18%, and the market size will reach US$2.2 billion in 2028.

Technology-driven increments

1.Intelligence and the Internet of Things

- Industrial Conveyor Belt Manufacturers will accelerate the integration of AI and 5G technologies. The cost of intelligent conveyor belts will drop by 40% in the next five years, driving the procurement volume of small and medium-sized enterprises to double, and the relevant market size will exceed US$2.5 billion in 2028.

- The delay of real-time data return is compressed to within 50 milliseconds, and the fault response rate is increased to 95%, becoming the core procurement standard for mining and logistics customers.

2.Material and process breakthroughs

- The proportion of carbon fiber core conveyor belts will increase from 3% to 12%, and the lightweight design will reduce energy consumption by 20%-25%, becoming the mainstream of the high-end market.

- The commercialization of bio-based rubber is accelerating, and by 2028, it will replace 10%-15% of traditional rubber raw materials, mainly used in the food and pharmaceutical industries.

Sustainability reshapes the competitive landscape

1.Policies and circular economy

- The EU carbon tariff (CBAM) forces Industrial Conveyor Belt Manufacturers to use more than 30% recycled materials, and the premium ability of compliant products has increased by 20%.

- The annual growth rate of the old belt recycling and remanufacturing market exceeds 10%. In 2028, the global recycling volume will reach 150,000 kilometers, and the remanufacturing cost will be reduced by 25%-30%.

2.Regionalized supply chain

- In order to avoid trade risks, leading manufacturers (such as Continental and Bridgestone) have built new factories in Southeast Asia and Mexico, and the proportion of localized production has increased to 50%-60%.

- The import dependence of South America and Africa remains above 80%, and the cost-effectiveness priority strategy has expanded the share of Chinese and Indian manufacturers to 55%.

7. FAQ

What is an industrial conveyor belt?

An industrial conveyor belt is a device used to transfer materials from one location to another, and is widely used in industries such as mining, manufacturing, logistics, agriculture, and food processing. It reduces manual labor and improves production efficiency through efficient and continuous material handling methods, and is an indispensable part of modern industrialized production.

Which industries use industrial conveyor belts?

Industrial conveyor belts are widely used in multiple industries, including:

Mining Industry: It is one of the main application industries of industrial conveyor belts, used to transport heavy materials such as ore and coal.

Building Material Industry: Conveyor belts are also often used to transport building materials such as sand, gravel, and concrete.

Fertilizer & Agriculture Industry: Conveyor belts play an important role in transporting agricultural products, fertilizers, and other materials.

Energy & Power Industry: In power plants and other energy facilities, conveyor belts are used to transport coal, oil, etc.

Forestry Industry: Conveyor belts are used to transport wood, wood processing products, etc.

Steel & Metallurgy Industry: Conveyor belts are widely used to transport raw materials such as iron ore, coal, etc.

Leadfill & Waste Treatment Industry: Used for the transportation and treatment of garbage and waste.

Coal Industry: Conveyor belts are used to transport coal, especially in coal mines and power industries.

Shipping & Port Industry: Used to transport goods at ports, especially bulk goods such as coal, grain, etc.

How to choose a suitable industrial conveyor belt?

When choosing a conveyor belt, you need to consider the following factors:

Material type: Different materials have different requirements for conveyor belts, for example, the transportation of coal, ore and food has different standards.

Working environment: The working environment has special requirements for conveyor belts, such as whether they need to be resistant to high temperature, low temperature, oil, anti-static, etc.

Bandwidth and carrying capacity: Choose a suitable conveyor belt according to the weight of the transported material and the bandwidth requirements.